Application:

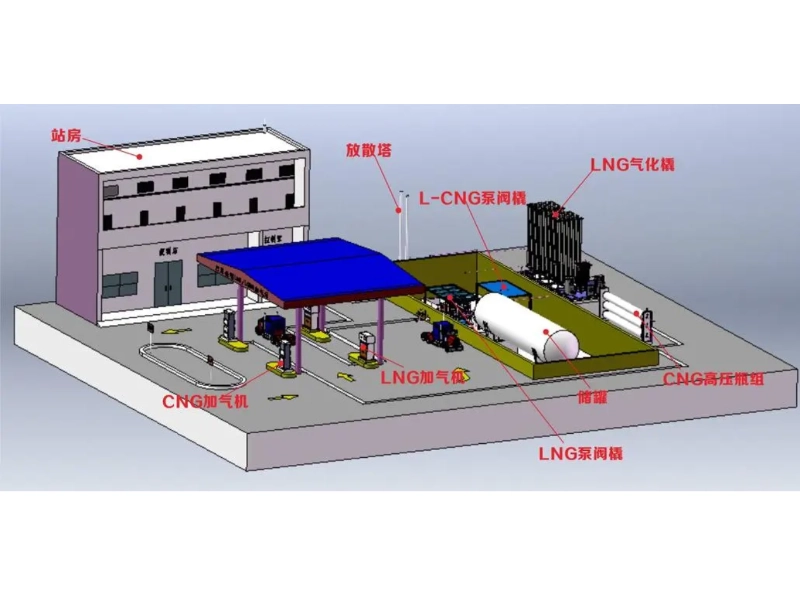

In order to make full use of the volatile flash vapour (i.e. BOG gas) in the LNG storage equipment, BOG can be boosted to a certain pressure by a compressor and then directly supplied to the city pipeline network, or it can be boosted to 25MPa and delivered to the CNG station for use.

The compressor for BOG recovery is divided into 4 basic types according to the normal working flow rate: 100Nm3/h (50~150Nm3/h), 300Nm3/h (200~400Nm3/h), 500Nm3/h (400~700Nm3/h), 1000Nm3/h (800~1500Nm3/h).

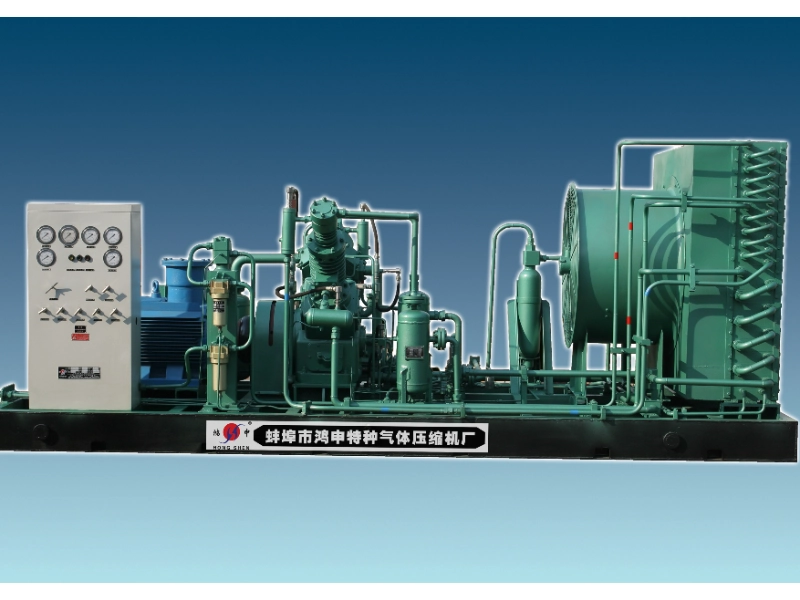

Widely used in LNG liquefied gas station, BOG gas small-displacement bottle filling, the machine has the characteristics of low energy consumption, low noise, low vibration, high reliability and easy operation.

Product features:

1, skid-mounted BOG compressor system, simple design, heavy duty, easy maintenance, long service life, suitable for BOG compression.

2, using 5-stage 5-cylinder V design, 5-stage compression reduces the compression ratio of each stage, reduces the exhaust temperature at all levels, and improves the compression efficiency.

3, suitable for low-pressure intake occasions (intake pressure of 1barG, exhaust pressure of 250barG, flow rate of 260Nm3 / hr)

4, full air-cooled design, without special installation foundation

5, host and system design to ensure high system quality.

6, Integral skid-mounted design, easy installation, and optional protective cover.

Design features:

Universal modular design brings more flexibility and simplicity in adjusting pistons, cylinders, cylinder heads and valve blades to provide a highly efficient and economical system.

-Easy to install and maintain

-Low maintenance and operating costs

-No special foundation requirements

-Pressurised crankcase to eliminate gas leakage

-High operating pressure

-Balanced design

-Low vibration

-Low compression ratio and temperature rise

-High efficiency

-Suitable for continuous or intermittent operation

-Low RPM for long service life

-Meets OSHA noise standards