Description of the unit:

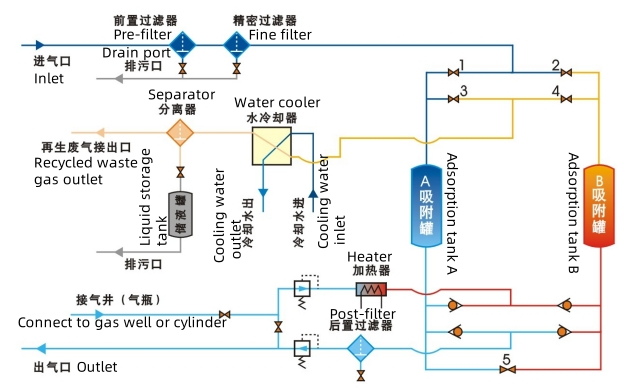

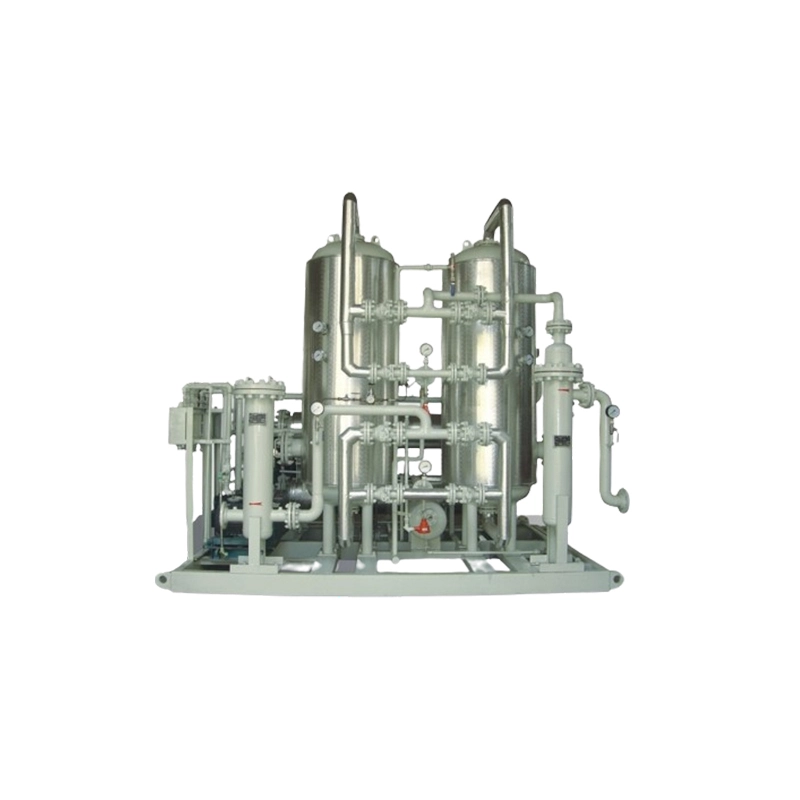

The post dewatering unit is located between the compressor outlet and the sequence control panel. This series of products is used when the pressure in the network is too low (the investment in front dewatering is too high) or when it is not possible to leave an interface between the compressor stages. This series of products have two types: manual and automatic, the adsorption cycle is 8-12 hours, and the vehicle type is 4-6 hours.

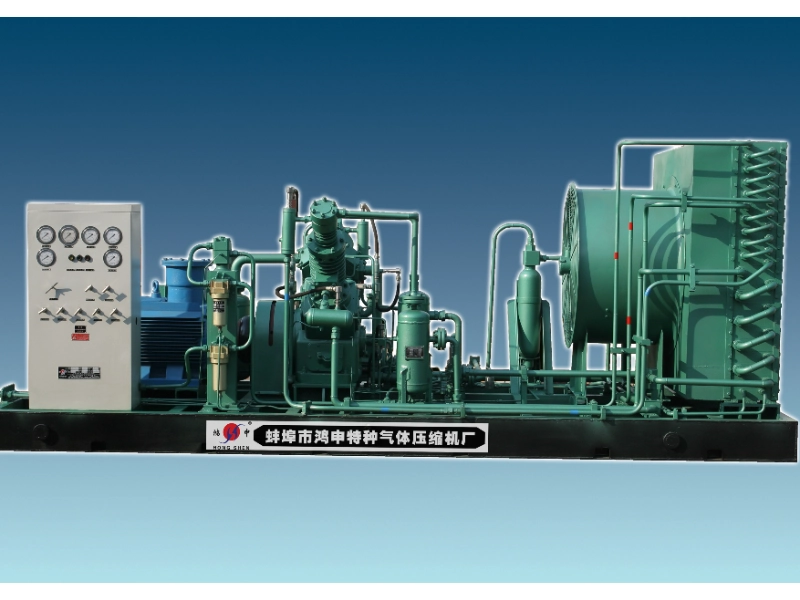

Oilfield gas lift compressor is a common piece of industrial equipment that works by compressing incoming air or gas to lift oil from the bottom of the well to the surface.