Device Description:

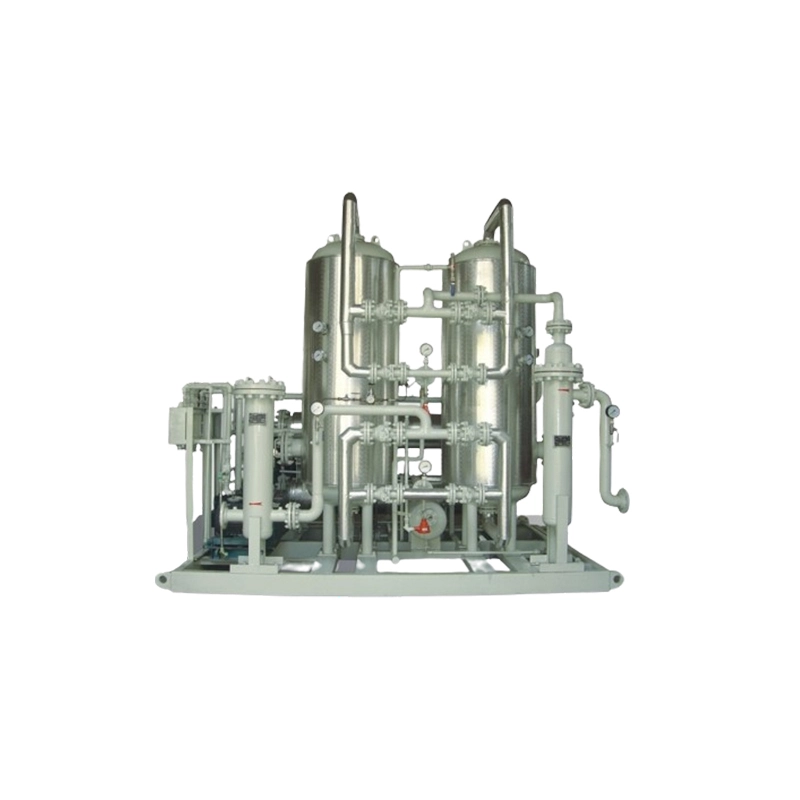

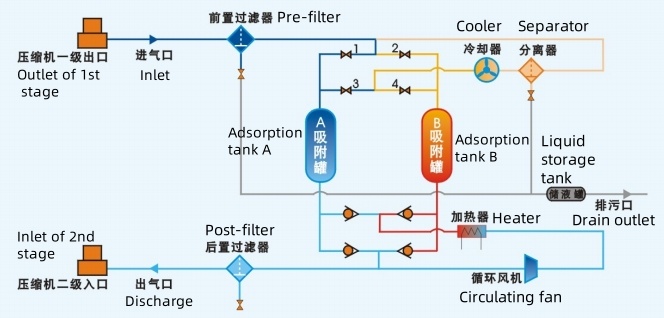

The interstage dewatering device is located at the first stage outlet of the compressor (it can also be set at the second stage outlet, and the working pressure is suitable for not more than 4.0MPa). This series is suitable for the city network whose pressure is too low (front dewatering investment is too high), and the compressor can leave the interface configuration.

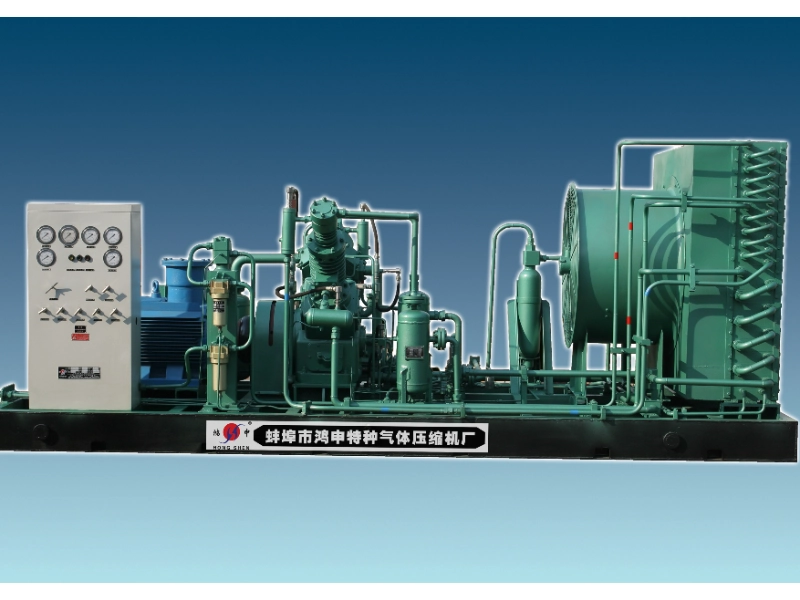

Oilfield gas lift compressor is a common piece of industrial equipment that works by compressing incoming air or gas to lift oil from the bottom of the well to the surface.