Oilfield gas lift compressor is a common piece of industrial equipment that works by compressing incoming air or gas to lift oil from the bottom of the well to the surface.

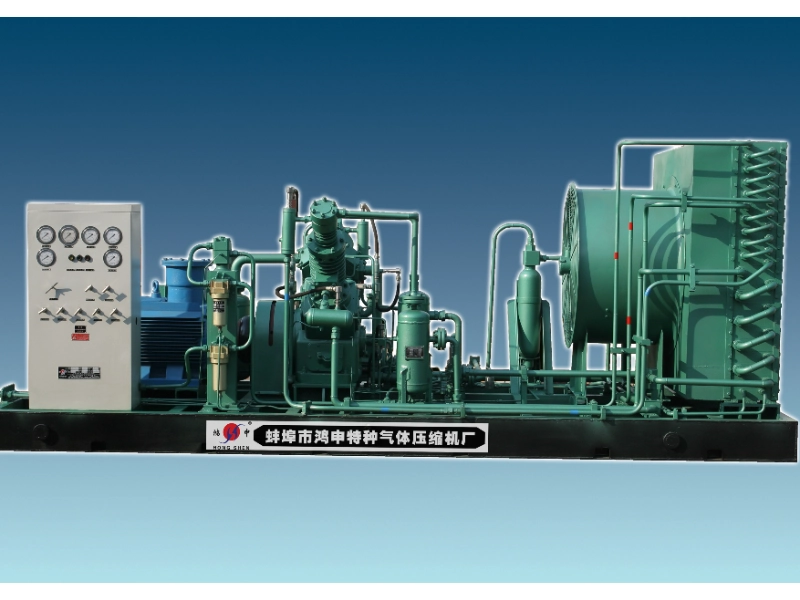

Natural gas compressors for L-CNG filling stations

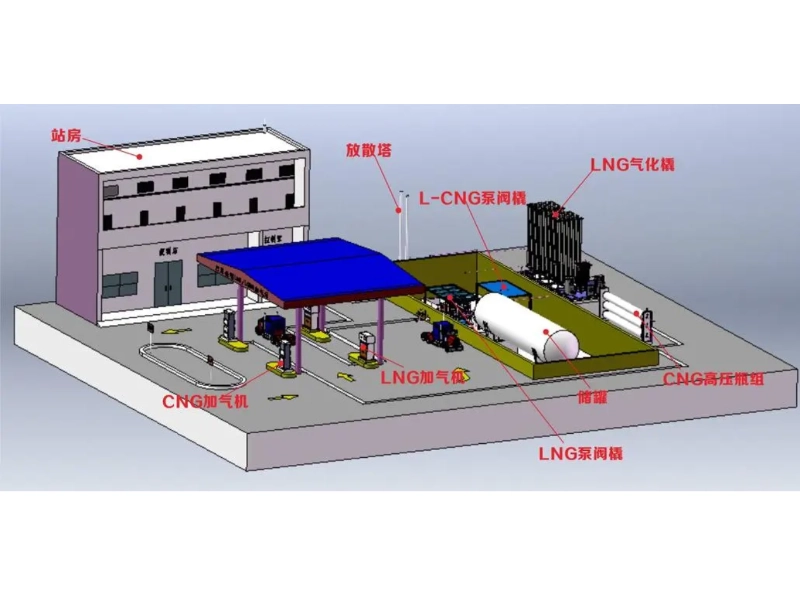

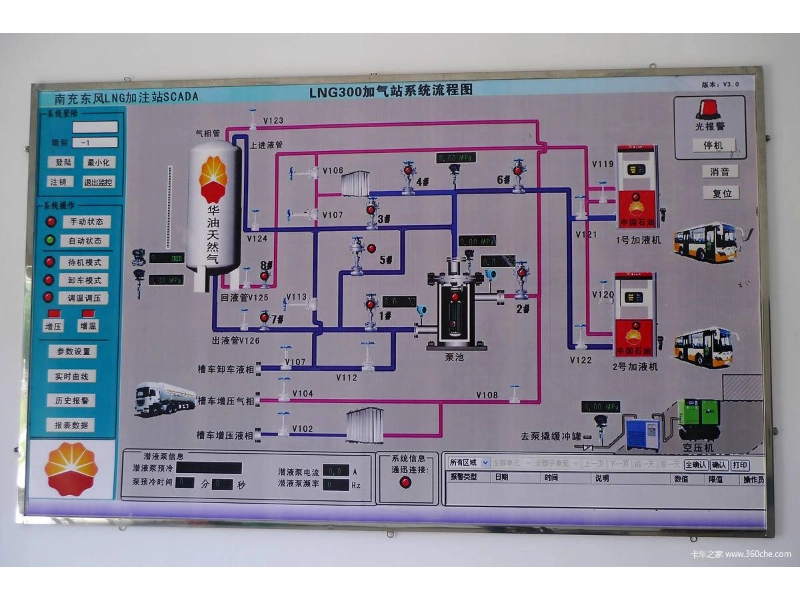

The process design scope of L-CNG filling station includes LNG unloading, storage pressurization, LNG filling, LNG plunger pump pressurization, high pressure gasification, CNG storage, BOG treatment, EAG treatment, dispersion system, pressure regulation measurement, etc.

The design process includes: LNG is transported by tank truck to the filling station. First of all, the LNG in the tanker is injected into the cryogenic LNG storage tank by the cryogenic submersible pump or pressure difference. Under non-working conditions, the storage temperature in the LNG tank is -162 ℃ and the pressure is normal pressure. Under working conditions, the pressure in the LNG storage tank is stable at 0.1-0.15mpa (if the following pressures are not explained, they are all gauge pressures). Then, the low-temperature LNG flows into the low-temperature hydrocarbon pump, is pressurized to 25.0Mpa by the pump, enters the main gasia, transforms into gaseous NG after heat exchange, and heats up to a temperature greater than 0℃ with a pressure of 25.0Mpa. Then it is automatically fed into the high, medium and low gas storage Wells through the sequence control panel, and distributed to the gas filler for automatic gas filling.