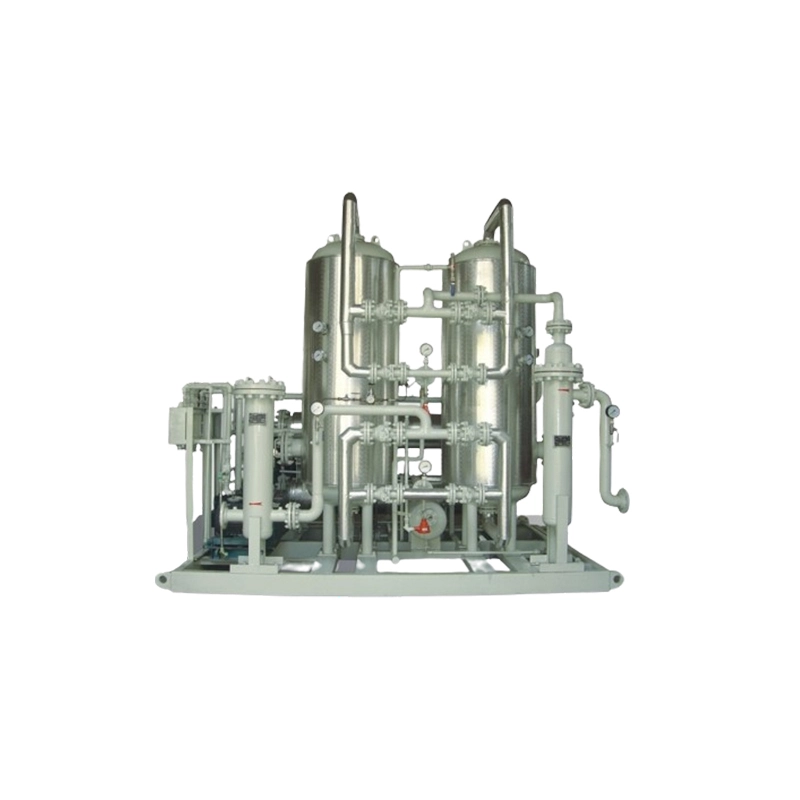

The semi-automatic equipment only requires the operator to manually switch the valves on site when switching between the two towers, and the regeneration process is automatically controlled. The equipment will release a small amount of natural gas when switching between two towers.

This series of products is suitable for gas stations with small investments and dedicated personnel for operation and maintenance.

In the chemical industry, compressors are used in a wide range of equipment and production lines. In addition, electronic equipment, metallurgy, construction and other industries also need to use compressors to process and produce products.